#EpicFail: Titanium Hydriding

This month we continue our #epicfail series on failure mechanisms looking at the effect of exposure to hydrogen on titanium alloys.

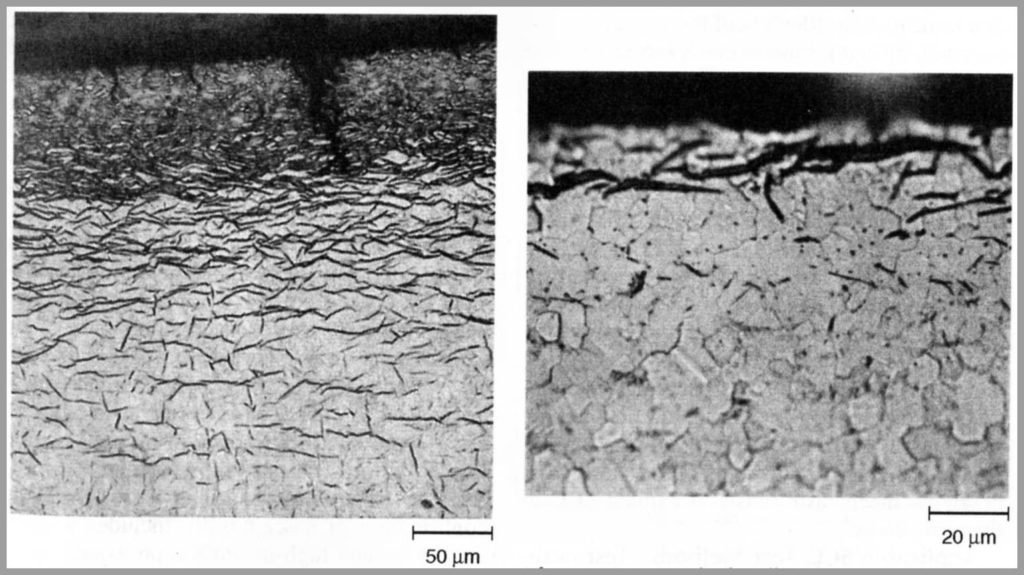

Hydriding of titanium is a metallurgical phenomenon in which hydrogen diffuses into the metal and reacts to form an embrittling hydride phase (see Figure 1). This can result in a complete loss of ductility with no noticeable sign of corrosion or loss in thickness. In January 2006, a serious incident occurred on an offshore gas production platform which involved the catastrophic failure of a shell and tube heat exchanger. The failure caused a significant and immediate gas release followed by ignition and an explosion. Fortuitously there were only two relatively minor injuries. The cause of the failure was found to be attributable to titanium hydriding.

Figure 1 – Hydrides in Titanium

Although titanium is generally considered to be reasonably resistant to chemical attack, severe problems may arise when titanium-based alloys are exposed to hydrogen-containing environments. The mechanism occurs at temperatures above 75ᵒC and at a pH below 3, pH above 8 or neutral pH with a high hydrogen sulphide content. Hydrogen absorption can also occur when the titanium alloy is coupled to a more active metal in an acidic solution. The solubility of hydrogen in pure titanium and alpha-beta alloys is limited (50 – 300 ppm) and once this is exceeded, hydride is formed. Beta alloys, on the other hand, are more tolerant of hydrogen and 2000 ppm can be tolerated.

Absorption of hydrogen by titanium dramatically increases once the protective oxide film normally present on the metal is damaged through either mechanical abrasion or chemical. Hydrogen intake is also accelerated by the presence of surface contaminants, including iron smears. The phenomenon can be minimised by anodising or thermal oxidising to increase thickness and resistance of the normally protective titanium oxide film.

To find out how R-TECH Materials can help you with a materials issue please feel free to contact us.