On-Site Support

R-Tech Materials has extensive experience of undertaking various on-site support activities whether it’s to complement our failure investigation and plant integrity work or simply to find out more about a component without having to destructively test it. This can be particularly helpful in large industrial plant and process lines where minimising down-time is critical.

R-Tech Materials offer the following techniques:

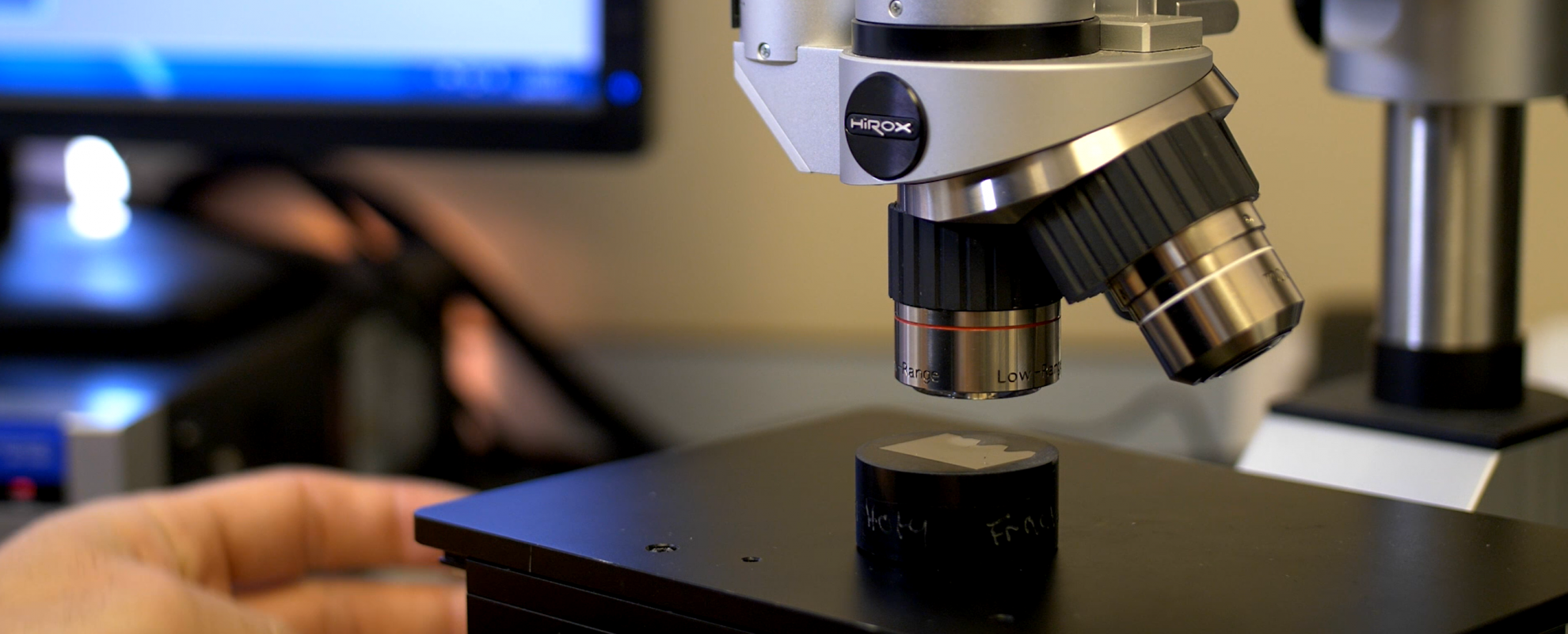

Replication Metallography

Having the opportunity to examine actual metal samples within a laboratory can provide detailed insight into any materials degradation, and the possible impact upon a component’s functionality. However, taking actual samples from an operational location is often not practical and could impair the integrity of the subject matter. The alternative to this is to replicate the preparation techniques used within a laboratory, in-situ directly upon the subject component. Utilising appropriate replication techniques, a specialist technician is able to take what is in essence a carbon copy of the underlying microstructure revealing damage mechanisms such as creep and thermal degradation processes such as carbide spheroidisation in carbon steels and sigma phase and carbide precipitation in stainless steels. R-TECH Materials have a breadth of experience in the application of this method to a wide range of materials. Want to find out more? Click here.

Positive Material Identification

R-Tech Materials offer Positive Materials Identification (PMI) in-situ by means of a portable X-Ray fluorescence spectrometer. Instead of reliance on paper work and marking systems, the manufacturer is required to demonstrate that the materials used for component manufacture is the correct material specified for the job. There are limitations with this technique, since it is unable to analyse for light elements such as carbon, aluminium and silicon. Nevertheless, for many industrially used metallic materials, the XRF technique can be used to verify whether or not the correct grade of material has been used. The results of the analysis performed on the component can be compared with reference samples, or can be compared with the library of alloy grades in the library of the instrument.

Portable Hardness Testing

R-TECH Materials is able to undertake hardness testing in-situ using equipment which measures hardness from the rebound of a ball from the test surface. The device is spring loaded, so that hardness can be measured on surfaces in any orientation. Conversions are available to gives results in the common hardness scales (Vickers, Rockwell etc). A typical application would be the measurement of the hardness of pipes in process plant as part of a condition assessment. Want to find out more? Click here.

Do our on-site support services sound like they could benefit your failure investigations or plant integrity work? Contact us today and someone from our team will be in touch to support your business needs.