Polythionic Acid Stress Corrosion Cracking (PASCC) is a form of intergranular cracking that affects austenitic alloys in environments containing sulphur compounds, particularly during shutdown or startup in high-temperature services such as petrochemical plants, refineries, and nuclear reactors. Though not commonly encountered under normal operating conditions, PASCC can lead to catastrophic failure if not properly understood and mitigated.

PASCC occurs due to the formation of sulphide scales in the presence of sulphur compounds which then react with air and moisture to form sulphur acids (polythionic acid). In industrial systems, especially those handling sulphur-containing hydrocarbons or sour gases, polythionic acids can form during shutdown when metal surfaces are exposed to air and moisture.

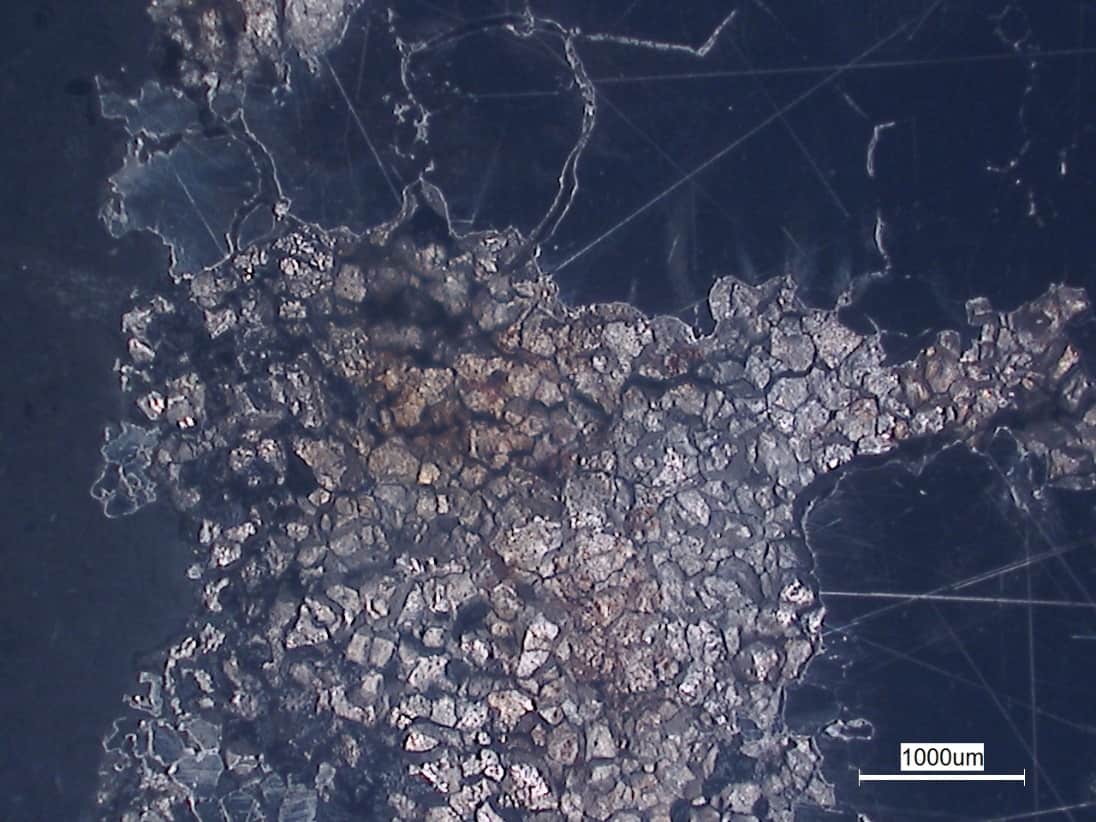

Polythionic acids attack sensitised austenitic stainless steels adjacent to the chromium depleted grain boundaries, producing an intergranular fracture. Upon exposure to the temperature range 450-900°C, precipitation of chromium carbides to the grain boundaries can occur which can lead to a phenomenon known as sensitisation. During carbide precipitation, interstitial carbon diffuses rapidly to the grain boundaries. However, since chromium is a substitutional element and diffuses very slowly, there is insufficient time for chromium to diffuse to the carbides from all over the grains. A high concentration of chromium in the carbide particles decreases the chromium content immediately adjacent to the grain boundaries. In these areas, the concentration of chromium falls below 10.5 wt% (the level at which stainless steels acquire their ‘stainless’ characteristic) and thus the depleted areas become anodic in the presence of an electrolyte and are susceptible to corrosion and is commonly termed sensitisation. The time at which sensitisation commences largely depends on temperature and chemical composition. Further, a tensile stress must be present for the mechanism to occur, this can either be applied or residual. The stresses may be internal or applied. Examples of internal stresses are those produced by deformation during cold work, by unequal cooling from high temperature and by internal structural rearrangements involving volume changes.

During high-temperature operation, sensitisation is often unavoidable. As a result, prevention of polythionic acid stress corrosion cracking relies primarily on effective shutdown practices and procedures. If potentially susceptible equipment is to be opened or exposed to air, preventive measures should be implemented to minimise or eliminate the risk of polythionic acid stress corrosion cracking (PTA SCC). Recommended practices include:

- Flushing the equipment during or immediately after shutdown with an alkaline solution (e.g., soda ash) to neutralise any polythionic acids formed upon exposure to air and moisture.

- Purging the equipment with dry nitrogen or a nitrogen/ammonia mixture during shutdown to prevent the ingress of air and the subsequent formation of polythionic acids.

These measures are in line with best practices outlined in NACE SP0170, which provides comprehensive guidelines for the prevention of PTA SCC in refinery equipment during shutdown and maintenance operations.

It is important to note that PASCC has also been observed in materials exposed to hydrogen sulphide environments without prior exposure to elevated operating temperatures. In such cases, sensitisation has occurred as a result of welding or inadequate heat treatment during fabrication or manufacture, rather than through high-temperature service exposure.

For welded components, the use of low-carbon (e.g., 304L, 316L) or stabilised grades (e.g., 321, 347) can significantly reduce the risk of sensitisation by minimising chromium carbide precipitation at grain boundaries. However, under elevated temperature service conditions, these grades only delay the onset of sensitisation—they do not eliminate it entirely. Prolonged exposure at sensitising temperatures can eventually lead to chromium depletion and increased susceptibility to intergranular corrosion mechanisms such as PASCC.

For more information or expert advice on PASCC and its prevention, feel free to contact us at info@r-techmaterials.com. Our team of specialists can assist with material integrity challenges and provide support to ensure the safety and longevity of your engineering systems.